If you’ve been in the 3D printing game for any length of time, you know the routine. You spend hours calibrating, slicing, and praying to the tech gods. You hit ‘print’. You wait. And then, you get one… single… object. You scrape it off the build plate (another prayer that it doesn’t break), and you start the whole song and dance over again.

It's a process. A labor of love, for sure. But what if it didn't have to be? What if your printer could just… keep going? What if it could print parts in a series, one after the other, without you having to intervene? What if it could print something as long as your dining room table?

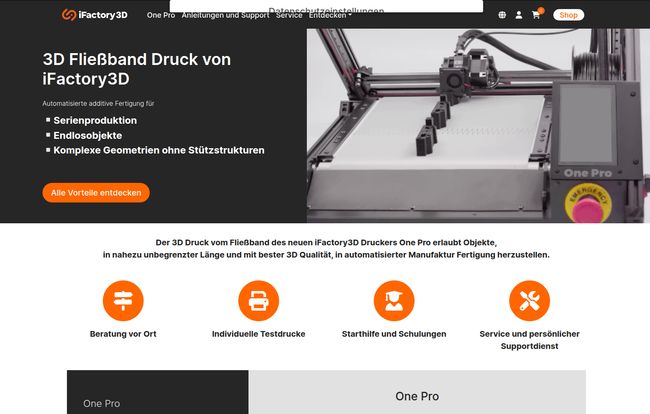

This isn't some far-off sci-fi dream. It's the reality of belt 3D printing, and a German company called iFactory3D is pushing this tech into the spotlight with its One Pro printer. I've been watching this space for a while, and honestly, it’s one of the most exciting developments in additive manufacturing I've seen in years.

So, What on Earth is a Belt 3D Printer?

Imagine your standard 3D printer’s build plate. Now, instead of a static, square piece of glass or metal, picture a conveyor belt. A Fließband, as the Germans would say. That’s the core of it. The printer head is tilted at an angle (usually 30-45 degrees), and it prints directly onto this moving belt.

As the object is printed, the belt slowly inches forward. When one object is complete, the belt simply carries it along and drops it into a catch bin at the end. The printer doesn’t stop; it just starts the next one. It’s like the difference between a craftsman building one chair at a time and a modern assembly line producing hundreds. The build plate is no longer a static stage; it’s a moving runway for your creations.

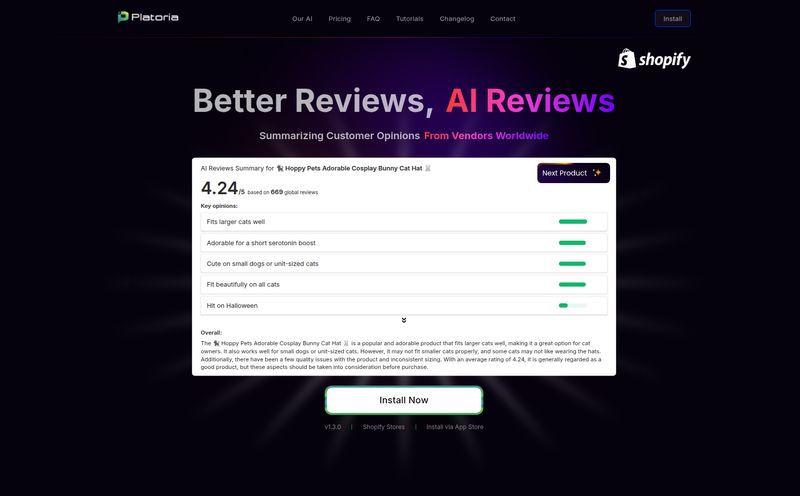

Meet the iFactory3D One Pro

This is the machine at the heart of iFactory3D's vision. The One Pro isn't just a concept; it's a fully-fledged piece of hardware you can buy right now. It’s pitched as a comprehensive solution for automated additive manufacturing, designed to tackle some of the biggest headaches of traditional FDM printing.

Visit iFactory3D

The Real Magic of a Moving Build Plate

Okay, a conveyor belt is cool, but what does it actually mean for your workflow? Three things, really.

First, automated serial production. This is the big one. You can queue up 10, 50, or 100 of the same part in your slicer software and just walk away. The One Pro will print the first one, roll it off the belt, and immediately start the next. For small businesses, engineers needing multiple jigs, or makers selling their creations on Etsy, this is a total game-changer. No more babysitting the printer and resetting it every few hours. It's a genuine “fire and forget” system.

Second, ridiculously long objects. Because the build surface is a belt that moves along the Z-axis, you're not limited by the physical height of the printer frame. Your Z-axis is, for all intents and purposes, infinite. Want to print a 6-foot-long architectural model, a full-scale sword prop, or a custom piece of trim? As long as you have the floor space for it to roll out, you can print it. This capability alone opens up a whole new world of projects that were previously impossible on a desktop machine.

Third, complex geometries with fewer supports. The 45-degree printing angle is a clever bit of engineering. It means that long, gentle overhangs that would normally require a forest of support material can often be printed without any supports at all. This saves a ton of filament, dramatically reduces post-processing time, and results in cleaner final parts. It’s a smarter way to build up layers.

Let's Talk Price: Is the One Pro Worth the Investment?

Alright, let's address the elephant in the room. This is not your entry-level Ender 3. The iFactory3D One Pro is a professional piece of kit, and it has a professional price tag. I’ve seen some people balk at the cost, but I think that’s missing the point. You're not just buying a printer; you're buying a manufacturing tool. You’re buying back your time.

Here’s a quick breakdown of what you're looking at, based on their online shop (prices in Euros, of course):

| Product | Price |

|---|---|

| One Pro 3D Printer | €4,748.00 |

| Enclosure for One Pro | €419.00 |

| Extension for One Pro | €299.00 |

| PETG Filament (1kg Spool) | €24.99 |

| Replacement Belt / Fließband | €109.99 |

The initial investment is significant, no doubt. But if you're a business that spends hours every week on small-batch production, you can see how the automation could lead to a very quick ROI. It's a calculation of value, not just cost.

More Than Just a Printer, It's an Ecosystem

One thing I appreciate is that iFactory3D isn't just slinging a machine and wishing you good luck. They've built out a whole ecosystem. You can get a custom-fit enclosure, which is essential if you plan on printing with temperature-sensitive materials like ABS. They offer extensions, their own branded PETG filament (a great, sturdy, all-around material), and even “Care Packages” with spare parts like nozzles. This tells me they're serious about supporting their users for the long haul.

The learning curve is a point to consider. This isn't a plug-and-play appliance. To get the most out of it, especially for complex serial prints, you’ll need to invest some time in understanding the software and the unique aspects of belt printing. It’s a tool for pros and dedicated prosumers, not for the casual tinkerer.

So, Who is This Really For?

I see a few key groups getting incredibly excited about this.

- Small Businesses & Entrepreneurs: Anyone running a print farm or selling physical products can immediately see the value. The ability to produce parts 24/7 without manual intervention is huge.

- Engineers & Designers: For rapid prototyping of multiple iterations or producing custom jigs and fixtures for a workshop, the One Pro is a workhorse.

- Architects & Artists: The ability to print massive, long-form models and sculptures is a creative superpower. Imagine printing a topographical map or a complex installation piece in one go.

This technology also points to a greener, more decentralized future for manufacturing. By printing on-demand and reducing waste from supports, the CO2 footprint can be lower. It's a step toward the idea of globally networked micro-factories, producing goods exactly where they're needed.

Frequently Asked Questions

- What is a belt 3D printer?

- It's a type of FDM 3D printer that uses a moving conveyor belt as its build surface instead of a fixed plate. This allows for printing continuous batches of parts or extremely long, single objects.

- How much does the iFactory3D One Pro cost?

- The core iFactory3D One Pro printer is priced at €4,748.00. Additional accessories like an enclosure and extensions are sold separately.

- Can the iFactory3D printer print really long objects?

- Yes. This is one of its primary advantages. Because the belt moves the print along the Z-axis, the length of the object is theoretically unlimited, constrained only by your physical space.

- What materials can I use with the iFactory3D One Pro?

- The company sells PETG, which is a versatile and strong material. With the optional enclosure to control the ambient temperature, you should also be able to print with materials like ABS and ASA. As always, check the manufacturer's official recommendations.

- Is the iFactory3D printer hard to use?

- It's more complex than a basic entry-level printer. While iFactory3D provides software and support, users should expect a learning curve to master the nuances of belt slicing and automated production for optimal results. It's designed for users with some existing 3D printing experience.

- What does 'serial production' mean in 3D printing?

- It refers to the automated production of multiple identical parts in a continuous sequence. Instead of printing one part, stopping, and starting again, a belt printer can produce a 'series' of parts without any human intervention between prints.

Final Thoughts

The iFactory3D One Pro isn't just an iteration on an old design; its a fundamental shift in what a desktop printer can be. It moves 3D printing from a tool for one-off creations to a genuine, small-scale manufacturing platform. The price will make it a considered purchase, but for the right user, the value proposition is undeniable.

I'm genuinely excited to see where companies like iFactory3D take this technology. It feels like we're on the cusp of the next big leap, moving past the novelty and into a new era of practical, automated, and distributed production. The future of making things might just be rolling off a conveyor belt in a workshop near you.